Notre passage en SCIC

Notre passage en SCIC

En décembre 2019, IREPA LASER s’est réinventée en devenant une Société Coopérative d’Intérêt Collectif (SCIC).

La SCIC, c’est l’innovation des femmes et des hommes au service de l’innovation technologique. C’est un moyen de fédérer des PME et des ETI en recherche d’innovation pour des performances économiques améliorées, grâce à notre expertise et à nos réussites.

Notre ambition : une logique de co-création et de partage des risques, mais aussi et surtout de partage des réussites au service du collectif.

Jean-Paul GAUFILLET, notre Président, s’exprime sur ce changement de statut :

Forum France Additive 2023

Le Forum France Additive, rendez-vous biannuel des acteurs de la fabrication additive, se tiendra du 4 au 6 juillet à Paris Saclay !

À cette occasion, ne manquez pas les interventions de nos experts :

- Jérôme Wursthorn — Integradde Project: A digital thread end to end

- Nathan Mayer — PAMPROD : Solution DED hybride pour la fabrication de pièces XXL

- Nicolas Villedary — AMFREE : Une solution DED innovante pour construire des pièces métalliques XXL

Au plaisir de vous y retrouver !

PLI Conférences 2023

Organisé par le Club Laser et Procédés, en partenariat avec Cailabs, l’Institut Maupertuis et Photonics Bretagne, PLI Conférences est le rendez-vous incontournable dédié aux procédés laser industriels et à leurs avancées.

À cette occasion, ne manquez pas les interventions de nos experts :

- Frédérique Machi — Réponse du soudage laser aux nouveaux marchés de l’énergie – Fiabilisation des innovations sur les liaisons hétérogènes

- Frédéric Mermet — Mise en forme de faisceaux laser femtoseconde « multipoints » : les clés pour une productivité industrielle ?

On vous donne rendez-vous les 27 et 28 septembre à Rennes !

Rencontre avec…

Lors de l’événement des 40 ans d’IREPA LASER, nous avons donné la parole à nos partenaires institutionnels et industriels !

- Anne-Marie Jean, Vice-présidente de l’Eurométropole de Strasbourg s’est exprimée sur la notion d’innovation et comment IREPA LASER s’inscrivait parfaitement dans cette démarche.

- Christophe Eschenbrenner, Responsable commercial senior 3DEXPERIENCE Marketplace Entreprise de chez Dassault Systèmes et Président de France Additive s’est exprimé sur cette technologie innovante qu’est la fabrication additive.

- Hervé Fraisse, Directeur R&D chez Aperam Alloys & Specialties nous parle de sa rencontre avec IREPA LASER, de son entrée dans la SCIC et du projet PAMPROD.

- Jean-Marc Staerck, Directeur technique chez Technogenia nous nous parle de son aventure avec IREPA LASER.

- Aurélien Fussel, Responsable de Programme – Fabrication Additive pour le secteur des pièces de rechange chez ALSTOM, s’exprime.

PROXI INDUS 2023

PROXI INDUS, le salon d’affaires sur-mesure pour les industries locales, se tiendra du 6 au 7 juin à Metz.

Au programme :

- Un hall d’exposition des technologies industrielles du moment.

- Des rendez-vous d’affaires préprogrammés qualifiés et ciblés

- Des repas affinitaires conviviaux pour du networking business

Venez rencontrer Louis Blanquinque, notre technico-commercial, pour échanger sur tous vos projets d’innovation et enjeux industriels !

>> Plus d’infos sur l’événement : https://www.proxi-indus.com/

La fabrication additive chez IREPA LASER

La fabrication additive chez IREPA LASER ? Ils en parlent !

- Christophe Eschenbrenner, 3DEXPERIENCE Marketplace sales manager chez DASSAULT SYSTEMES et Président chez FRANCE ADDITIVE

- Hervé Fraisse, Directeur R&D chez Aperam Alloys & Specialties

- Aurélien Fussel, Responsable de programme – Fabrication additive pour le secteur des pièces de rechanges chez ALSTOM

40 ans d’innovation – Ils en parlent !

IREPA LASER a récemment soufflé ses 40 bougies…

40 ans d’innovation, ça représente quoi pour vous ?

On a posé la question à :

- Ambroise Vandewynckèle, Responsable des procédés de fabrication avancés chez AIMEN Centro Tecnológico

- Aurelien FUSSEL, Responsable de programme – Fabrication additive pour le secteur des pièces de rechanges chez Alstom

- Christophe Eschenbrenner, 3DEXPERIENCE Marketplace sales manager chez Dassault Systèmes et Président chez France Additive

- Olivier Fréneaux, fondateur d’IREPA LASER / Conseil en Stratégie et Financement de l’Innovation chez SFI CONSEIL

Salon du Bourget 2023

La 54ème édition du Salon International de l’Aéronautique et de l’Espace se tiendra du 19 au 25 juin 2023 au Parc des Expositions de Paris-Le Bourget.

Organisé par le SIAE, filiale du GIFAS (Groupement des Industries Françaises Aéronautiques et Spatiales), cet événement réunit l’ensemble des acteurs de l’industrie mondiale autour des dernières innovations technologiques.

IREPA LASER sera présent sur l’espace d’AERIADES, un réseau regroupant des entreprises, centres de transfert de technologies, établissements d’enseignement et de recherche unis par leur volonté de renforcer et développer la filière aéronautique en Région Grand Est. Pour rencontrer nos experts, rendez-vous Hall 2B CD 32 !

Les 4 premiers jours du salon seront réservés aux professionnels suivis de 3 jours pour le grand public.

Découvrez les exposants AERIADES :

- 4CAD

- ASI GROUP

- BOURGUIGNON BARRE

- CIMULEC

- DEGOISEY

- FPS

- FTV

- GMT

- IREPA LASER

- IRT M2P

- KTIS

- MONTEC

- NIMESIS TECHNOLOGY

- PRECI3D

- SMC

- SUDP

- TCM

- THERMO EST SN

>> Plus d’infos : https://www.siae.fr/

Le réseau Carnot

IREPA LASER est membre de l’Institut Carnot MICA et est très fier de faire partie du réseau Carnot.

L’Institut Carnot MICA est une structure de recherche publique qui accompagne les entreprises dans le développement de leurs projets Recherche et Développement. MICA est expert des matériaux fonctionnels, des surfaces et interfaces et procédés associés, de la recherche fondamentale à l’application industrielle.

L’institut accompagne les entreprises tout au long du processus de R&D, grâce à une offre complète et unique :

- Programme de R&D

- Prestations de service, expertises et conseils

- Transferts de technologies

- Productions pilotes

- Formations initiales et continues sur mesure

- Aide à la recherche de financement

MICA participe à accroître la compétitivité du tissu économique et industriel français.

L’institut est composé de 18 membres, dont 9 laboratoires de recherche et 9 centres techniques (CRT/CTI) dont IREPA LASER est très fier de faire partie. Chaque année, cette structure d’excellence permet à 900 entreprises de bénéficier des partenariats avec les meilleurs laboratoires (matériaux) et leurs plateformes de haute technologie.

L’Institut Carnot MICA est membre du réseau Carnot, qui est composé de 38 instituts implantés dans chaque région en France. Ces structures de recherche publique apportent leurs technologies mais aussi les compétences de leurs équipes de recherche au service des entreprises (de toutes tailles et tous secteurs). Le réseau Carnot s’engage également à “développer une activité de recherche partenariale au bénéfice de l’innovation des entreprises” ainsi que d’accroître l’impact économique des projets R&D. Le réseau Carnot propose une large palette de compétences qui répondent aux besoins des entreprises en termes de recherche et innovation.

>> En savoir plus sur l’Institut Carnot MICA : www.carnot-mica.fr

>> En savoir plus sur le réseau Carnot : https://www.lereseaudescarnot.fr/fr

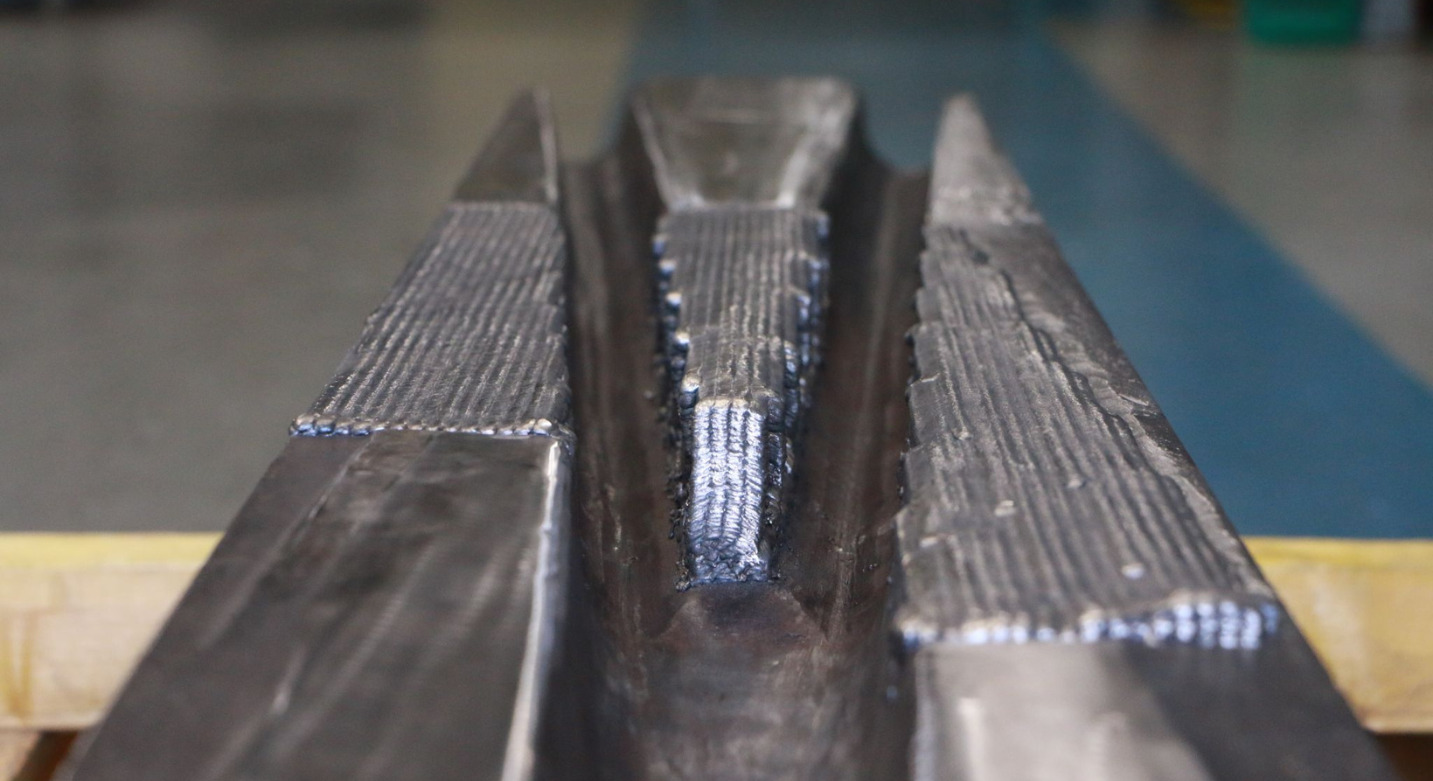

AM fast train part 5

Challenge completed!

Bastien GERARD, Group Business Development Director Consumables at Welding Alloys France, tells us all about this great adventure:

“Welding Alloys have a wealth of expertise in the development and manufacture of flux cored #welding wires. With more than 50 years of experience, Welding Alloys are well positioned to provide tailored solutions dedicated to increasing resistance to wear such as abrasion, erosion, friction, impact and more.

Innovation is part of the DNA at Welding Alloys. Cored welding wires are continuously developed, to provide unique solutions capable of solving even the most challenging wear problems faced in many industries.

In the railway industry, crossings or frogs are subject to daily metal-to-metal wear and impact. Consequently, they become worn and there is an increased risk of damage or potential breakages. Refurbishment by weld rebuilding is a solution that saves time and money. Restoration and repair of the crossing can be swiftly carried out in-situ, resulting in reduced maintenance downtime and track closures, and increased cost savings.

However, at a certain point, the crossings will need to be replaced. The old crossing is then recycled. Wire Laser Additive Manufacturing (WLAM) provides a new way of recycling crossings and frogs in the workshop, offering a better solution for the #environment.

This case study partners Welding Alloys’ advanced cored wires with the high-tech equipment from IREPA LASER and highlights the advantage of WLAM in the regeneration of an old crossing initially allocated to waste.”

Congrats to the team!

Actualités

Voir toutes les actualitésPourquoi choisir IREPA LASER ?

Approche pragmatique

Précurseur technologique

Services personnalisés

Solutions innovantes

Engagement impartial