AM fast train part 4

AM fast train part 4

The challenge goes on…

Nathan Mayer, our engineer, takes us on our latest additive manufacturing journey…

- Ready to start manufacturing!

“No specifical tool is necessary to install the part, we just lifted it and put it on the machine table. I took my references on the part and I’m ready to start, just must select my robot program and press “cycle start”.

After 10 hours, the rail is repaired, the built geometries match perfectly with the rail profile. All the data as TCP position, wire feeding speed, laser power, traveling speed are saved during the operation. It guarantees the process according to the qualification parameters and gives us the opportunity to identify any deviation or defect during the deposition. Learning from those data after any manufacturing operation allows us to improve process knowledge and skills and make it evolve.”

>> https://www.youtube.com/watch?v=rUjcOrI5Kp0

Keep going!

Stay tuned for a few words from our partner Welding Alloys France…

Business Industries Saint-Nazaire 2023

L’événement Business Industries, un salon industriel et des rendez-vous d’affaires organisés, se tiendra du 13 au 14 avril à la base sous-marine de Saint-Nazaire.

Au programme de cette 5ème édition :

- L’espace machines-outils – robotique & équipements de production avec des machines en fonctionnement

- Le village start ’up & solutions innovantes

- Un espace dédié au mix énergétique

IREPA LASER sera présent sur le stand B14 ! Nos experts mettent à profit leur expérience de plus de 30 ans dans le soudage laser, pour vous proposer des solutions industrielles sur mesure et vous accompagner dans vos projets de développement et d’industrialisation de produits.

Notre approche industrielle innovante et pragmatique ainsi que nos équipements de pointe (plus de 20 lasers, robots, laboratoires d’analyse et de caractérisation), font d’IREPA LASER une plateforme opérationnelle de premier plan pour prendre en charge la production de vos pièces, de la petite à la grande dimension, et réduire ainsi vos délais d’industrialisation.

Nos expertises :

- Soudage laser multi matériaux

- Acier, aluminium, inox, cuivre, nouveaux matériaux

- Expertise matériaux

Nos moyens :

- Une équipe pluridisciplinaire

- Un parc-machine avec des équipements performants

- Une capacité de production

- Un contrôle qualité continu

- Des parcours de formation adaptés

>> Plus d’informations sur l’événement : https://www.businessindustries-saintnazaire.com/

SIFER 2023

Le Salon International de l’Industrie Ferroviaire (SIFER) se tiendra du 28 au 30 mars à Lille Grand Palais.

Prenez une longueur d’avance dans vos projets d’innovation et retrouvez IREPA LASER sur le stand du réseau des Carnot : 1-456.

>> Plus d’infos

À cette occasion, ne manquez pas le pitch de Nicolas Villedary, en charge de la valorisation de la fabrication additive XXL d’IREPA LASER sur la sécurité améliorée et qualifiée par la réparation du rail (rechargement en fabrication additive sur grandes pièces) le 29 mars à 14h45.

>> Plus d’infos

APS Meetings 2023

IREPA LASER participe à APS Meetings 2023.

APS Meetings, la convention d’affaires dédiée à la fabrication additive, à l’impression 3D, au prototypage rapide et au développement produit, se tiendra du 29 au 30 mars à Lyon.

Nos experts sont à votre écoute pour tous vos projets et problématiques d’affaires, que ce soit dans le domaine de la défense, l’automobile, l’électronique, le rail, le médical ou encore l’aéronautique.

Nous avons hâte de vous rencontrer !

>> Plus d’infos : www.apsmeetings.com

AM fast train part 3

The challenge goes on…

Nathan Mayer, our engineer, takes us on our latest additive manufacturing journey…

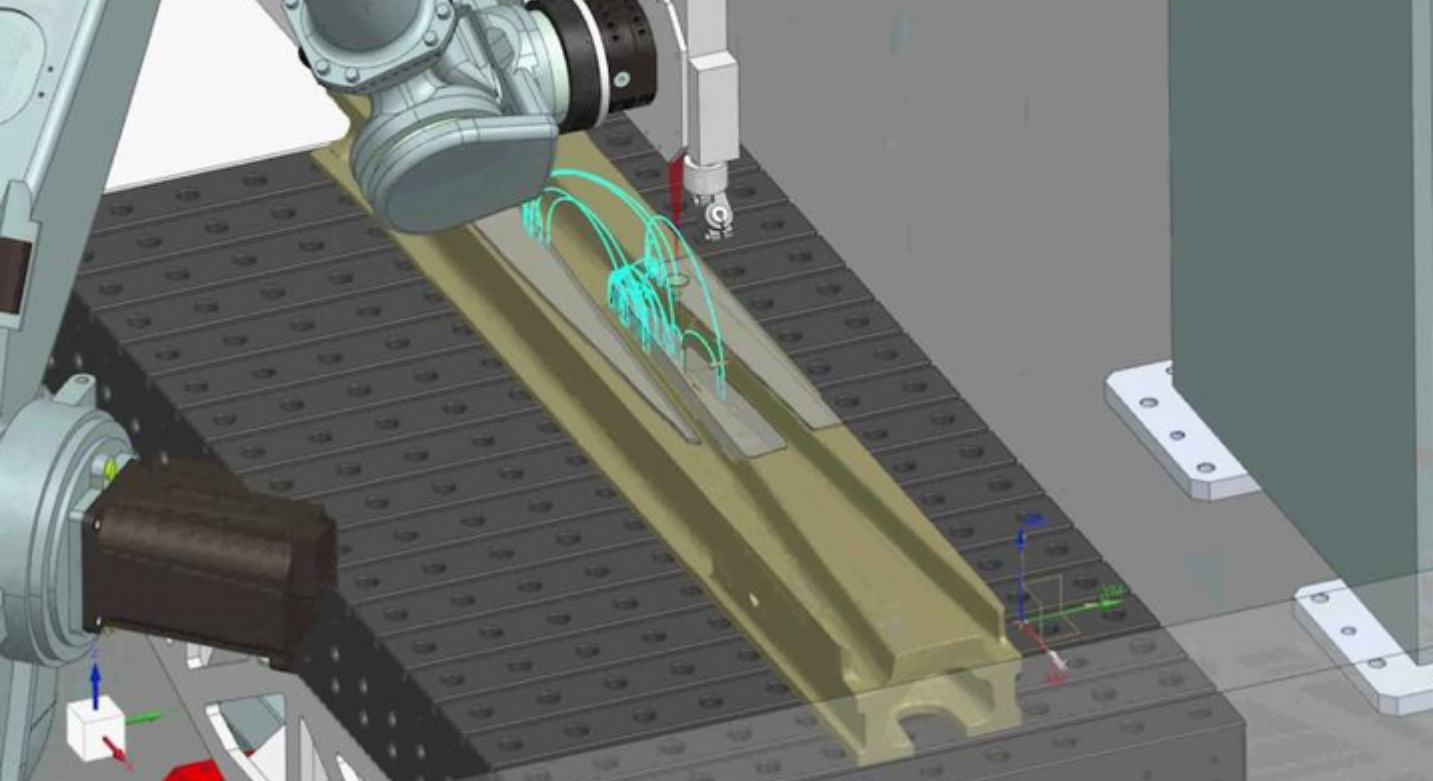

- It’s time for simulation!

“The CAM part will be simplified due to several advantages of our WLAM process:

- Close to the final dimensions

- High deposition rate possible ➝ beyond 600cc/h

- Low dilution and manageable heat input

- Good mechanical characteristics

Exaggerating a bit, with the right deposition parameters, it will be like generating a path for a 3D printer. Once the building strategies are selected, the parameters filed and the trajectories generated, it’s time to apply some rules to our robots and simulate the operation to avoid any singular point or collision. The part is long (approximatively 2 meters) and the volumes to build are long too, so I generated the toolpath to have the longest deposition tracks and few “off-moves”.

Parameters and toolpath trajectories verified, I can post process my robot program and go back from the numerical world. Rail must now be installed on the machine and repaired!”

>> https://www.youtube.com/watch?v=EOu4dzMt2co

Keep going!

Stay tuned for the next phase…

Integradde final event

INTEGRADDE FINAL EVENT – The future of European Manufacturing: Enabling Advanced Innovations in 3D Printing

On Tuesday, Mar 14, 2023, the H2020 INTEGRADDE project is holding its Final Event in Brussels (hybrid, format). The event will take place from 09:30 to 14:30 at La Tricoterie. The event is supported by the European Factories of the Future Research Association (EFFRA) and European Association of the Machine Tool Industries and related Manufacturing Technologies (CECIMO).

The conference (which will include different discussions and a networking lunch) will bring together high-level policymakers, industrial actors, research institutions, and other relevant stakeholders to exchange views on the current most compelling issues related to 3D Printing in the manufacturing sector.

This event will offer a networking space for like-minded people within the manufacturing industry while showcasing the latest advancements in Additive Manufacturing, the project’s achievements and upcoming test-before-invest opportunities from related EU projects for technological innovations. The event will also offer an overview on the current and future positing of 3D printing from the perspective of some of the most accredited voices in the industry.

A detailed agenda of the event can be found here.

If you would like to find out more about 3D printing in manufacturing and network with your peers, register here!

AM fast train part 2

The challenge goes on…

Nathan Mayer, our engineer, takes us on our latest additive manufacturing journey…

- Preparation is done, let’s make a clean 3D model!

“For the further operations, it’s important to have a clean 3D model with the missing volumes on the part well defined and smooth. Nothing difficult with a CAD software for an advanced designer. We need to extract to worn faces from the STL and “stretch” them to the initial dimensions.

Before any CAM operations, working parameters must be known and the quality of the deposited material checked. To set them, I will do a quick test to identify a window of working parameters with which we get:

- “Good” linkage with the support

- No defect (lack of fusion, crack, porosity, etc…)

- Constant deposit geometry

- Acceptable deposition rate (the key to have a fast operation…)

To check all of this, build samples are cut, polished, and etched to observe them under microscope. It will be also interesting to check to hardness “as deposited”, to identify any deviation from the material datasheet.”

>> https://www.youtube.com/watch?v=xFg7Esp7xcw

Keep going!

Stay tuned for the next phase…

AM fast train part 1

Hello new challenge!

Nathan Mayer, our engineer, takes us on our latest additive manufacturing journey…

- Day 1: first exchanges

“We’re contacted by the company Welding Alloys France, a global leader in the production of advanced welding consumables, automated welding equipment for wear protection, the provision of engineered wear services, as well as wear plates, pipes, and components.

Their issue? They need to repair a worn #railway that has lost its geometry and they decided to go with the laser technology, most precisely additive manufacturing, instead of most conventional technologies.

Today, repairing or rebuilding parts are major players in increasing service times, avoiding waste and reducing carbon emissions. Railways are subject to heavy loads and many cycles; they must be hard and resistant over time and after 28 years, this one has significant missing elements, it is no longer new… To be used again, we must return to the original shape.

Can we really do it? Can we return to its original shape? Is the reconstruction going to be as resistant as the original one? Only time will tell but we’re up for the challenge.”

- Day 2: first reflexions

“Laser metal deposition or the DED additive manufacturing process offer many possibilities and one of them is to be able to deposit on an existing part. Instead of building complete parts, it is possible to rebuild and repair existing ones. Our wireframe laser additive manufacturing (WLAM) process will hopefully be able to help us with the reconstruction and gives back the used railway its original shape.

As for the material for the reconstruction, it must be just as resistant as the original. After a conversation with Welding Alloys France, they tell us they can provide us with the best yarn to fit this application. It is a manganese #steel that hardens on impact. This filler material is commonly used with conventional welding processes, and I think it will be interesting to show the results obtained with our deposition process, using wire and a laser.”

- Day 3: preparation

“As a first step, the rail must be prepared before the repair operation. So, the team starts to gouge and grind, but also learn its geometry by 3D scanning and digital reconstruction. Everything goes smoothly and we’re quite hopeful for what comes next.”

>> https://www.youtube.com/watch?v=zw2PFFyK3tc

Stay tuned for the next phase…

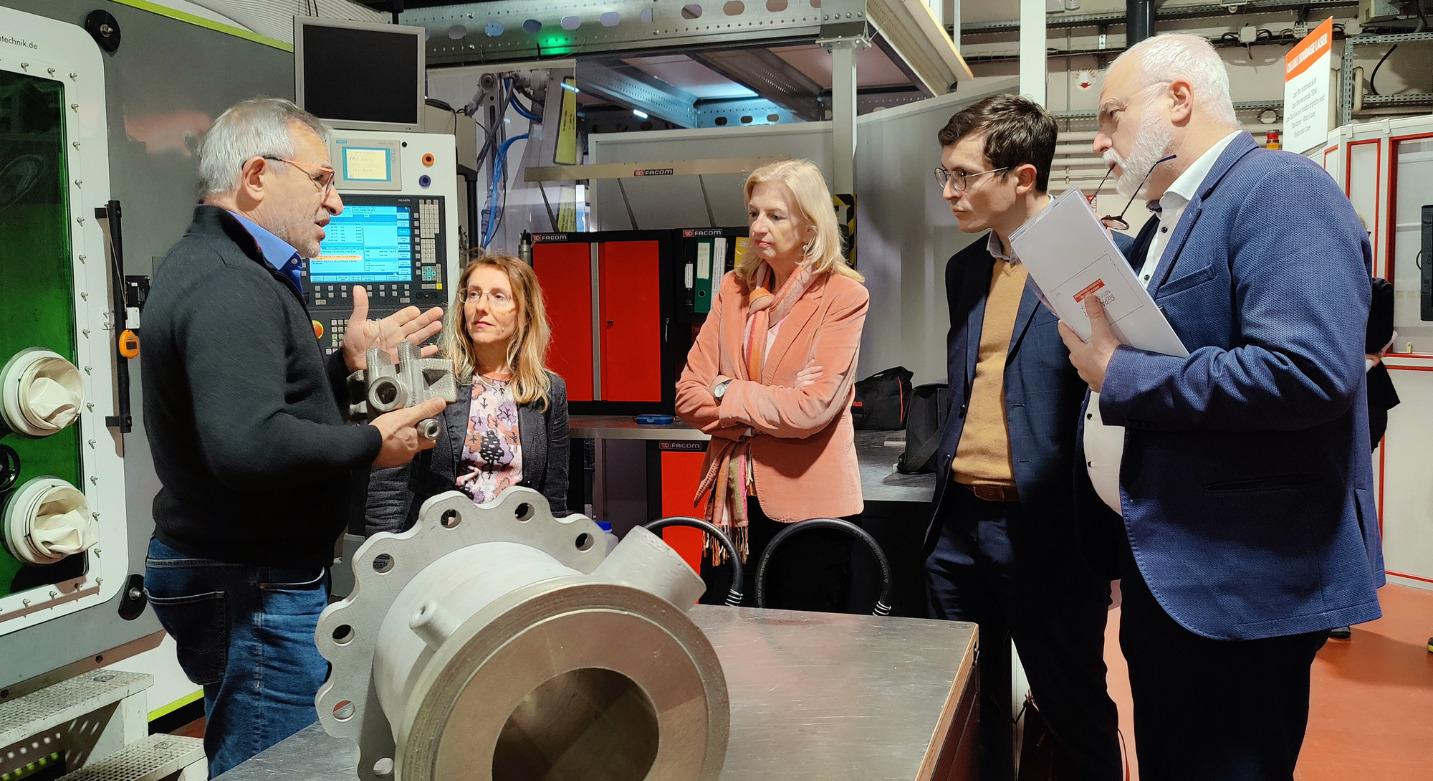

Visite de l’Eurométropole de Strasbourg

L’Eurométropole de Strasbourg en visite à la SCIC IREPA LASER !

Le 5 janvier, IREPA LASER a eu le plaisir de recevoir la visite de Pia IBMS, Présidente de l’Eurométropole de Strasbourg, accompagnée d’Anne-Marie JEAN, Vice-Présidente en charge des politiques de l’emploi, formation, économie durable et transition écologique des entreprises, de Matthieu RUDLER, Coordinateur du pôle transition écologique territoriale et de Philippe PORTELLI, Chef du service Enseignement supérieur, Recherche et Innovation.

Notre Président, Jean-Paul GAUFILLET, et nos équipes ont ainsi pu présenter notre modèle de Société Coopérative d’Intérêt Collectif, un statut innovant dans le domaine de l’innovation et du transfert de technologie.

Cette visite a également été l’occasion de mettre en avant nos savoir-faire lors d’un parcours guidé dans nos ateliers avec des démonstrations sur machine, des vidéos et des rencontres avec les experts.

Une belle rencontre lors de laquelle nos collaborateurs ont pu partager leur passion pour la technologie laser !

Lancement de l’initiative Grand Est Transformation Industrie

Le lancement de l’initiative Grand Est Transformation Industrie a eu lieu lors du salon BE 4.0 Salon Industries du Futur à Mulhouse (Grand Est) fin novembre 2022 !

Le dispositif GET lancé par la région Grand Est a pour vocation de relever les grands défis de la transformation environnementale, transformation digitale et transformation de l’industrie vers le 5.0.

La fabrication additive est mise à l’honneur dans ce dispositif :

- En accompagnant les offreurs de solutions innovants du Grand Est dans leur développement économique

- En connectant les offreurs de solutions aux entreprises et aux collectivités du Grand Est pour accélérer leur transformation industrielle

- En rapprochant les offreurs des acteurs et laboratoires académiques

Notre expert en fabrication additive, Didier Boisselier, est intervenu lors de la table ronde aux côtés de Claude Barlier – INORI, Bruno Flan – Platinium 3D, Stéphane Fontaine – Arts & Métiers Metz, Boris Ravignon – Région Grand Est, Jean Rottner – Région Grand Est et Alain Skiba – Alchimies.

Actualités

Voir toutes les actualitésPourquoi choisir IREPA LASER ?

Approche pragmatique

Précurseur technologique

Services personnalisés

Solutions innovantes

Engagement impartial