Hello new challenge!

Nathan Mayer, our engineer, takes us on our latest additive manufacturing journey…

- Day 1: first exchanges

“We’re contacted by the company Welding Alloys France, a global leader in the production of advanced welding consumables, automated welding equipment for wear protection, the provision of engineered wear services, as well as wear plates, pipes, and components.

Their issue? They need to repair a worn #railway that has lost its geometry and they decided to go with the laser technology, most precisely additive manufacturing, instead of most conventional technologies.

Today, repairing or rebuilding parts are major players in increasing service times, avoiding waste and reducing carbon emissions. Railways are subject to heavy loads and many cycles; they must be hard and resistant over time and after 28 years, this one has significant missing elements, it is no longer new… To be used again, we must return to the original shape.

Can we really do it? Can we return to its original shape? Is the reconstruction going to be as resistant as the original one? Only time will tell but we’re up for the challenge.”

- Day 2: first reflexions

“Laser metal deposition or the DED additive manufacturing process offer many possibilities and one of them is to be able to deposit on an existing part. Instead of building complete parts, it is possible to rebuild and repair existing ones. Our wireframe laser additive manufacturing (WLAM) process will hopefully be able to help us with the reconstruction and gives back the used railway its original shape.

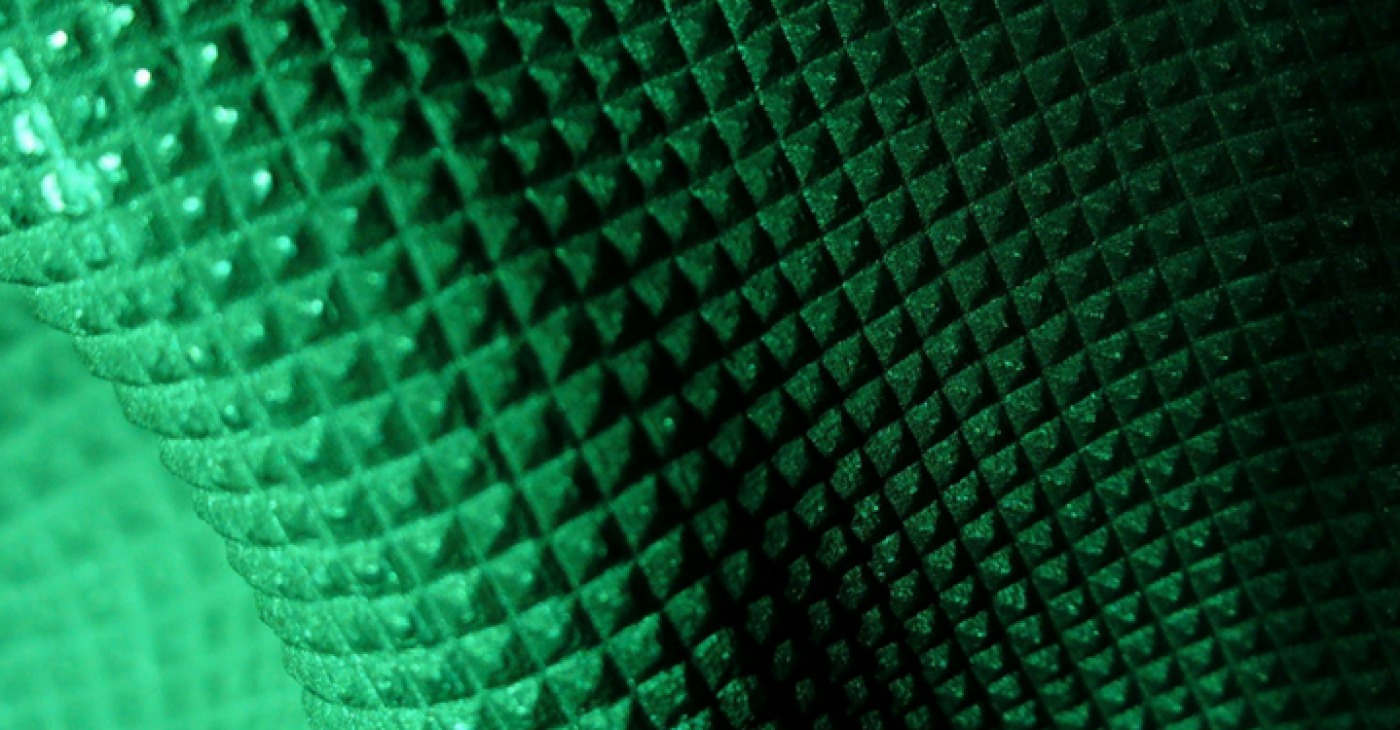

As for the material for the reconstruction, it must be just as resistant as the original. After a conversation with Welding Alloys France, they tell us they can provide us with the best yarn to fit this application. It is a manganese #steel that hardens on impact. This filler material is commonly used with conventional welding processes, and I think it will be interesting to show the results obtained with our deposition process, using wire and a laser.”

- Day 3: preparation

“As a first step, the rail must be prepared before the repair operation. So, the team starts to gouge and grind, but also learn its geometry by 3D scanning and digital reconstruction. Everything goes smoothly and we’re quite hopeful for what comes next.”

>> https://www.youtube.com/watch?v=zw2PFFyK3tc

Stay tuned for the next phase…