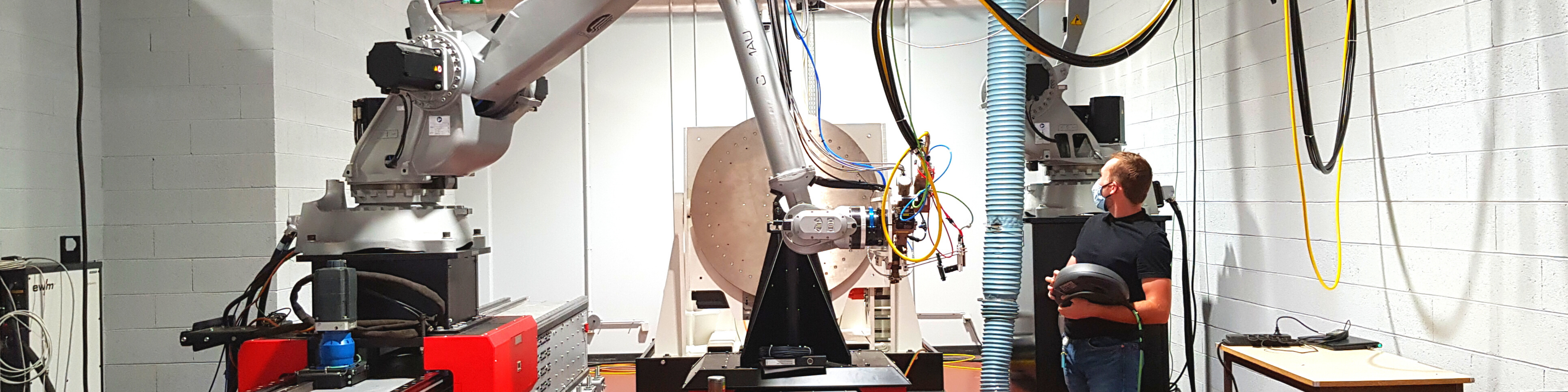

6 partners, experts in their fields, pool their know-how to design a multi-robot additive manufacturing solution.

PAM-PROD (Additive Manufacturing Processes – Productivity), is a machine that manufactures large-sized parts that are successful on the first try in additive manufacturing.

This initiative responds to the demand of many industrial sectors such as aeronautics, energy or defense, to be able to have machine solutions capable of producing large-dimension parts by AM (up to 5 meters) with a major stake: be able to use these systems in a production environment with controlled costs and competitive manufacturing times.

Designed to be flexible and agile

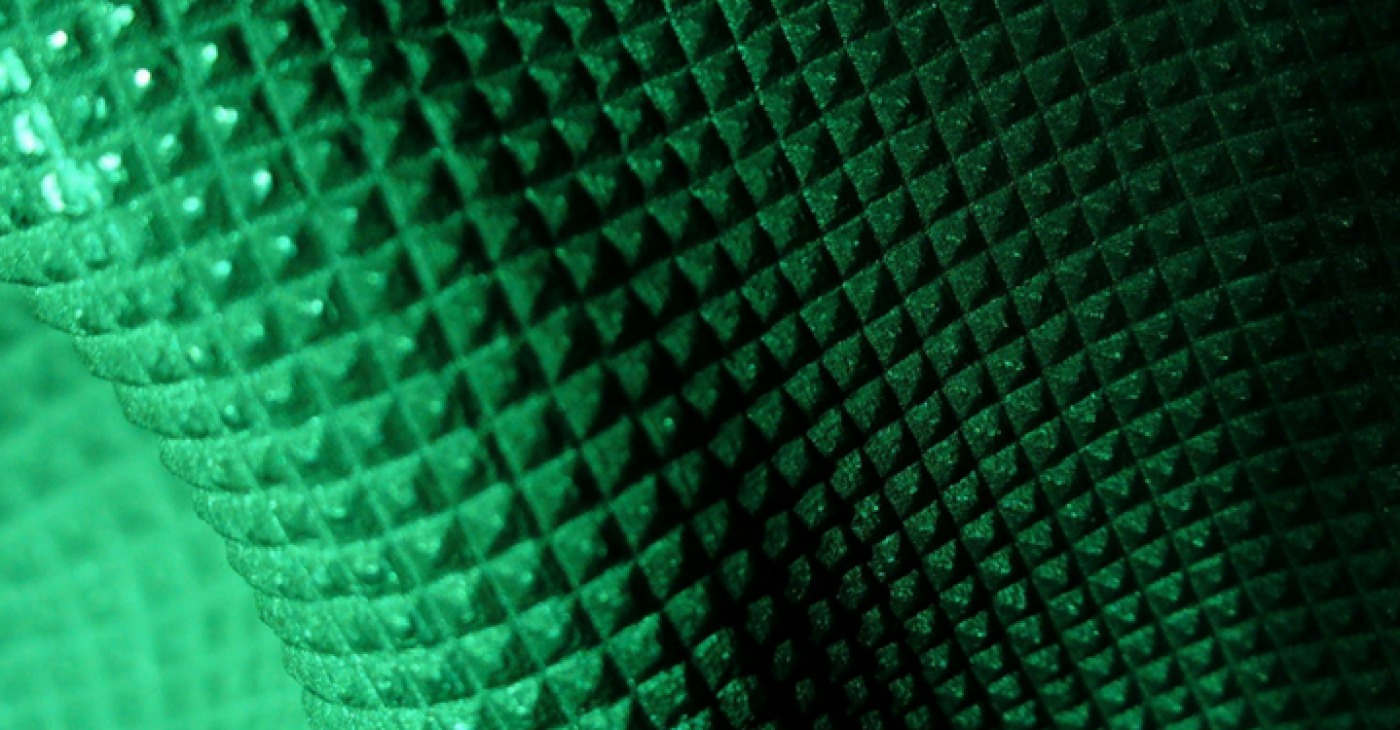

PAMPROD uses a hybrid additive manufacturing solution that combines both powder and wire deposition. The machine is specifically designed to be both flexible and agile. To increase a user’s return on investment, PAMPROD can be used with specialty metals, including the wide range of Nickel alloys for additive manufacturing that Aperam offers as either a powder or wire. PAMPROD can also be used with Titanium alloys and materials as stainless steel and steel.

A proof-of-concept machine has been installed at IREPA LASER. Prodways is bringing the PAMPROD solution to market by 2023.

Why choose PAMPROD?

To ensure a robust, repeatable manufacturing process, the machine is equipped with cameras that are directly linked to monitoring software designed by TPSH. This allows the user to monitor the deposits in the melt pool in real time. A thermo-mechanical simulation completes the whole process before the part goes into production.

It is this combination of additive manufacturing technology and adaptability that allows PAMPROD to reduce costs and lead times.

About the PAMPROD project

The project is the result of a consortium of six companies:

- Aperam : manufacturing and adaptation of material consumables

- Estia : piloting of robotics

- Institut Jean Lamour : materials expertise and mechanical testing

- IREPA LASER : machine and process development and numerical simulation

- Prodways : machinery manufacturing

- TPSH : real-time process control and monitoring

The PAMPROD project was coordinated by Aperam and IREPA LASER and received funding from BPI (Banque publique d’investissement).