Additive manufacturing has to face an economic imperative which is to manufacture functional parts of large dimensions good on the first try (metallurgical quality, geometry, …).

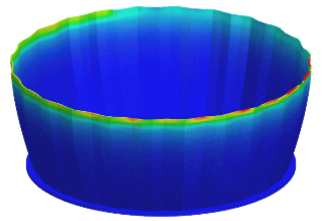

IREPA LASER has developed new methods unique in the world of thermomechanical simulation for DED processes. Thanks to these new tools, it is possible to calculate very quickly the thermomechanical constraints from the DED additive manufacturing trajectories.

This information is decisive in the choice and optimization of manufacturing strategies and the control of dimensions.

Contact us