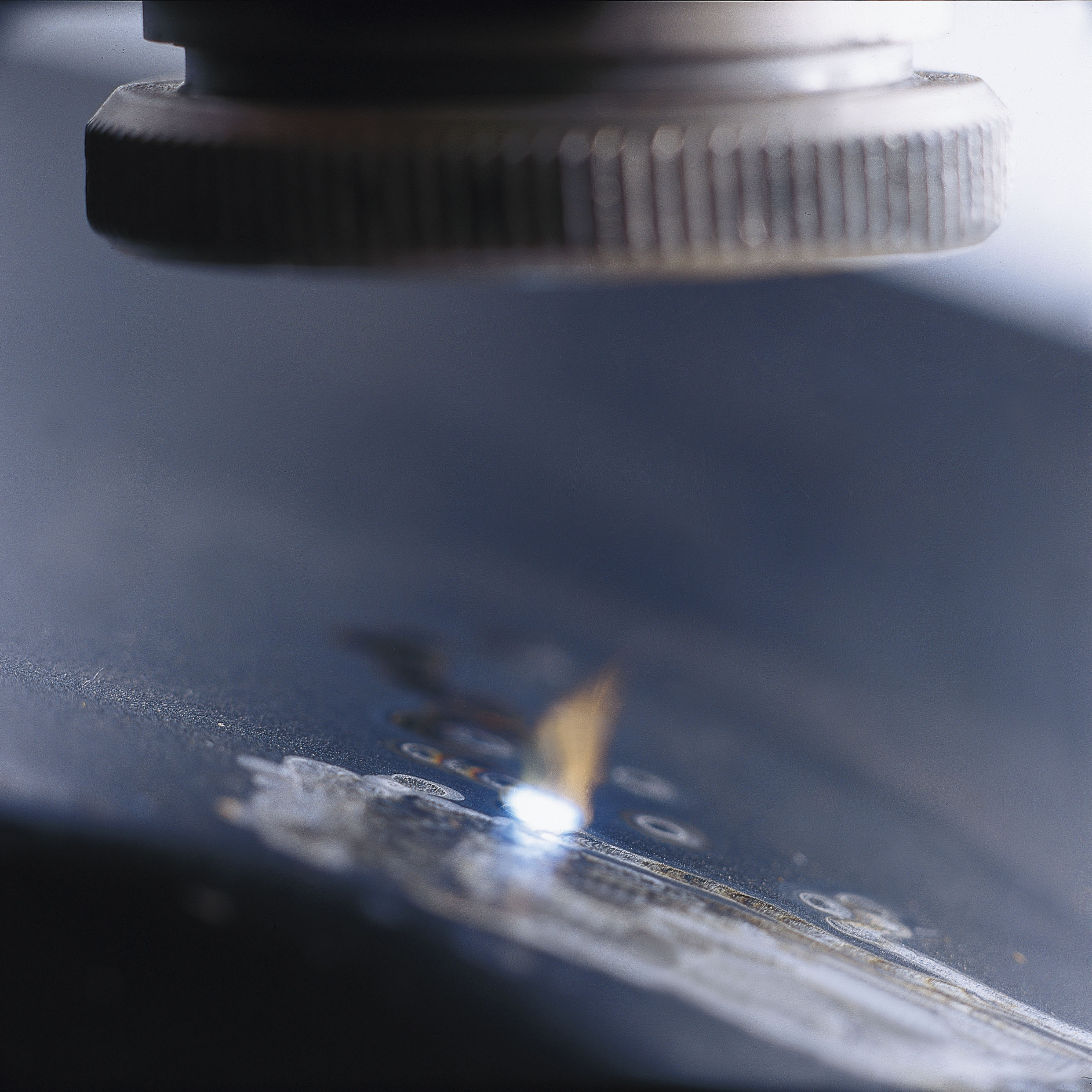

Laser stripping / cleaning

Protecting the integrity of a surface when it is being cleaned is a target that can be achieved with laser technology. There are different treatments depending on the nature of the materials, the material to remove from the surface and the degree of cleanliness required.

- Keeps the surface safe

- Contactless process

- No solvent

Contact us Download datasheet (pdf)