« Manufacturing processes and materials hybridization » conference

« Manufacturing processes and materials hybridization » conference

March 22 to 23, 2017 – Lyon (France)

Didier BOISSELIER, Application and Development Manager for Additive Manufacturing at IREPA LASER, will present « Manufacturing processes and materials hybridization: development and opportunities with CLAD® process » on 22th March 2017 in Lyon during APS Meetings.

APS Meetings is a business convention for additive manufacturing, 3D printing, rapid prototyping and product development

IREPA LASER’ experts will answer all your questions at their booth.

Abstract:

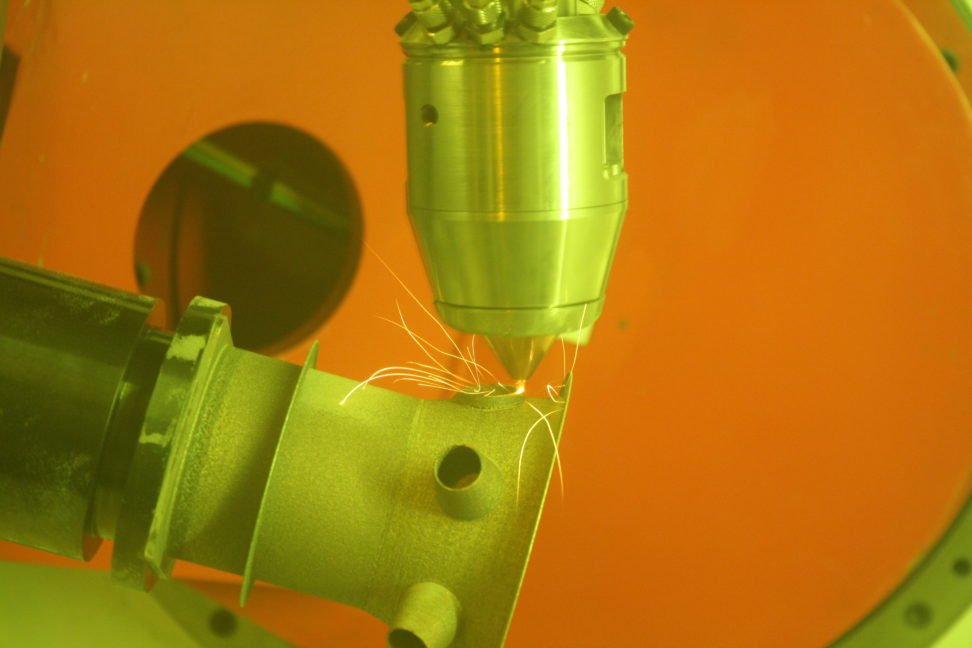

Pushing the limits of the processes by combining them so as to get the most from each of them and to optimize the manufacture of the parts. Pushing the limits of the materials by combining them to get the targeted properties according to the stresses of the part. The hybridization of processes and materials makes it possible to offer new solutions in the manufacture and optimization of parts.

About the event:

- Date: March 22-23, 2017

- Sector: Additive manufacturing, 3D printing, rapid prototyping, product development

- Location: Lyon, France

- Participants : Online registration

Consult the program HERE.

The Optical Safety and Laser at Work Days

March 28 to 29, 2017 – Bordeaux (France)

The Optical Safety and Laser at Work Days (JSOL) organized by the National Optical Safety Committee (CNSO) will take place on 28th and 29th March 2017 in Bordeaux. IREPA LASER is a member of the organizing committee and the scientific committee. The objective of this event is to promote a culture of prevention in laser and optical safety.

For health and medical services, auditoriums control rooms, and more generally health practitioners, the JSOL will present the risks associated with the use of lasers or optical sources and regulatory developments. This colloquium will propose plenary sessions composed of applied conferences including testimonies of prevention practices carried out in the field. An exhibition space will be dedicated to safety equipment and measurement of artificial optical radiation.

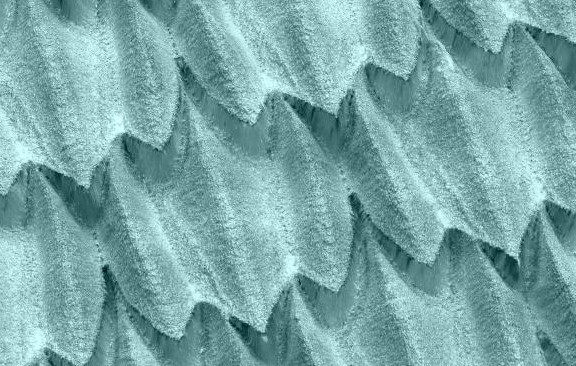

3D surface functionnalization

A new 5-axis industrial machine and a femtosecond laser now operational at IREPA LASER. The research and development center specialized in laser applied to materials takes a new step towards the industrialization of laser processes for the industry.

IREPA LASER continues to deploy its Alsace 3D development plan. After the “Metal Additive Laser Manufacturing” (FAML 2020) program, the development center launched ISurf (Intelligent surface functionnalization) and recently equipped itself with a 3D 5-axis texturing machine for finishing operations. IREPA LASER continues to deploy frugal solutions to produce technical parts at a lower cost.

The arrival of this new machine, financed by the State Region Contract Plan, is a real added value for the treatment of surfaces. It allows IREPA LASER to propose to its customers the machining or the fine marking in 3D of metallic or polymer parts, on simple or complex profiles, without discontinuity. The precisions thus obtained are of the order of a micron and can be rendered virtually invisible to the naked eye.

Advantages of the process:

- 3D machining of complex profiles,

- Addition of material,

- All materials,

- Global or localized 3D treatment.

For more information, click HERE.

ESPACE LASER 2017

FAIR AND SEMINARS

September 2017, 12-14 | Strasbourg

The European Trade Fair for Laser Processing in the Industry of the Future

From design to manufacturing, laser machines are part of a comprehensive interconnected system: laser machines, robots, scanner systems, inspection systems, 3D vision, virtual reality, safety equipment, software… A complete value chain is present at ESPACE LASER.

Resolutely industrial, ESPACE LASER is the only trade fair in France dedicated to materials and laser techniques for the industry. It displays all the production techniques and new laser additive manufacturing technologies for the development and rapid production of complex parts and customized products.

ESPACE LASER reinforces its European dimension. Thanks to a partnership developed with LASYS, the leading German trade fair for laser materials processing, both German exhibiting companies and German industrial visitors will participate in the 2017 edition of ESPACE LASER.

The « JNPLI » seminars

ESPACE LASER hosts the European conference « JNPLI » on the 13th and 14th September. Meeting place of experts, it presents the latest innovations and applications recently implemented in the field of industrial laser technologies and processes.

An exclusive and comprehensive program with the contributions from the best experts and an effective and targeted networking.

The organizers are : Club Laser & Procédés (CLP), the European Material Reasearch Society (E-MRS) and the research and development centre IREPA LASER. JNPLI 2017 is supported by the Laser Institute of Stuttgart (IFSW).

About the event:

-

- Date: 12-14 September 2017

- Topic: Laser Processing in the Industry of the Future

- Schedule: Tuesday and Wednesday from 9am to 6pm and Thursday from 9am to 5pm

- Location: Convention and exhibition center, Place de Bordeaux 67082 STRASBOURG

- Attendees: free badge request

- Exhibitors : registration contract request

For more information, click HERE.

Radiation Protection Network

October 7, 2016 – Lille

The University Hospital of Lille will welcome members of the Radiation Protection Network of Nord-Pas de Calais on October 7, 2016. The program includes conferences on security and radiation protection issues as well as booths managed by professionals from medical, industry, nuclear power and research fields.

During this day, our expert in laser safety and in charge of our training center, Franck RIGOLET, will present the various regulations in terms of laser safety.

About the event:

- Date: October 7, 2016

- Topics: Safety and Radiation Protection

- Location: CHRU Lille – GERNEZ RIEUX Institute, rue du Docteur Schweitzer 59037 LILLE

What is R2Nord network?

The Competent People in Radiation Protection (PCR) and actors of radiation protection don’t feel recognized enough and often run into difficulties because of a constantly changing regulation.

Thus, regional networks were created to organize days of exchanges, to form working groups…

Since 2012, the Nord-Pas-de-Calais has set up its network: the R2Nord, a multisector non-profit organization (health, research, industry…).

For more information, click HERE.

ICALEO – Laser Microprocessing Conference

October 16-20, 2016 – San Diego (USA)

During ICALEO, the International Congress on Applications of Lasers & Electro-Optics, Camille HAIRAYE, doctoral student at IREPA LASER, will present her work regarding laser texturing using a high power femtosecond fiber laser to create superhydrophobic surfaces.

About the event:

- Date: October 16-20, 2016

- Topics: material processing by laser, laser micro machining, nanofabrication

- Location: Sheraton San Diego / San Diego CA (USA)

- Attendees: academic researchers and industrials interested by laser technology

More information: www.lia.org/conferences/icaleo

Laser Microprocessing Conference – October,19

Microprocessing for Biological Applications Session

Abstract :

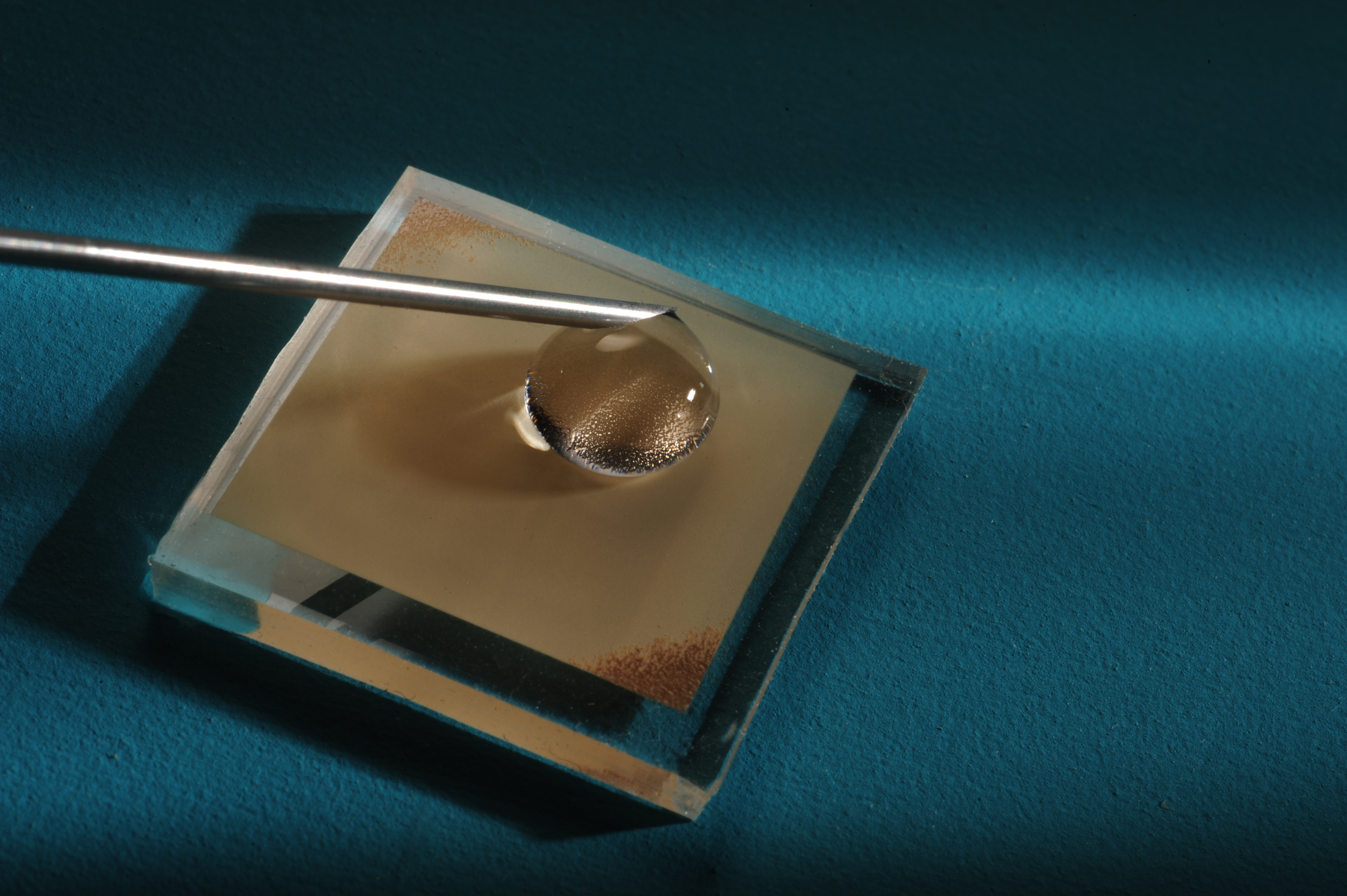

« Controlling the wettability of stainless steel by surface texturing using a high power femtosecond fiber laser »

In our study a high mean power diode-pumped Ytterbium fiber laser, integrated in micro-machining platform, has been used to texture stainless steel samples. It produces laser pulses of hundreds of femtoseconds in the near-infrared, with a repetition rate up to 2 MHz and a maximal energy of 150 µJ. Several authors have reported that superhydrophobic effect is obtained by the generation of self-organized micrometric structures. Nevertheless it is possible to improve the process rate by producing structures with designed geometries: the microstructures are thus generated by successive ablations of the material. With appropriate process parameters, it is easy to produce a superimposed self-organized nanostructures, which confers to the surface a dual-scale roughness, responsible for high hydrophobicity, with a contact angle as high as 160°.

By modeling the wetting behavior of a droplet on a microstructured surface by finite elements method, we illustrate the trend for the microstructure to enhance the initial wetting property of the surface. The evolution in time of the surface property after laser irradiation, related to surface chemistry, cannot be avoided but can be accelerated under certain conditions.

The production of a superhydrophobic behavior on non-flat surfaces at a reasonable rate, in conditions compatible with a production environment, remains a challenging issue. We will present a few hints toward such a goal.

Education in photonics

September 13, 2016 – Paris

As part of DEFI Photonics, a day of discussion and reflection is organized for companies and professional instructors in photonics. The objective of this day is to allow the main stakeholders in demand to connect.

The program includes presentations and discussions on the development of training, examples of actions in favor of training for the photonics business, corporate accounts and exchange of good practice.

On that day, our training manager, Franck Rigolet, will make a presentation of the RETALI (Technical Manager on industrial laser applications), a certified training under professional contract.

MICRONORA 2016

September 27-30, 2016 – Besançon

Come and meet IREPA LASER during MICRONORA 2016, international microtechnology trade fair. Located in hall C – booth 508, on the collective stand of the Club Laser & Procédés, our experts will be at your service.

About the event:

- Date: September 27–30, 2016 – Open to the public from 9am to 6pm

- Sector: microtechnology

- Location: Parc des Expositions Micropolis / Boulevard Ouest – Besançon (France)

- Attendees: free badge request

Micronora is highly specialized in the precision and miniaturization sectors and is the only trade fair in France to offer such an exceptional array of innovative technologies. Thanks to the transfer of solutions between different industrial sectors, micro and nano-technologies can be applied in all cutting-edge sectors looking for smaller, more accurate, more intelligent solutions. Micronora is the ideal place to find out more about them. Over 25 000 m² of exhibition space, the exhibitors, 34% of whom are from overseas, display their varied, high-quality innovations – from R&D to sub-contracting and production technologies.

More information : www.micronora.com

Conference « Laser & Medical » – September, 28

During MICRONORA, the Club Laser & Procédés is organizing conferences about the topic: « Lasers in the medical field ». Our expert in micro-applications, Frédéric Mermet, will present the ABLALASE project regarding kidney surgery with lasers.

Abstract:

Lasers have many benefits for partial surgery for kidney cancer, such as the nano-invasive aspect, the ability to incise tissue and cauterize, etc… A bibliographic review regarding laser interaction on biological tissues will be presented during this talk. The research works’ results carried out under this project, where different wavelengths and transmission schemes have been implemented on kidneys, will also be detailed.

About the workshop:

Laser technology is increasingly being used in health and medical equipment fields to treat some diseases or to machine, mark or assemble implant components, prostheses and surgical instruments. Without reviewing exhaustively all laser applications in medicine, this half-day of 10 conferences aims to inform manufacturers on recent developments in this field.

European Forum on Additive Manufacturing

21 to 23 June 2016 – CentraleSupélec Chatenay Malabry

IREPA LASER attends the European Forum on Additive Manufacturing. This event which is organized by the French association on rapid prototyping and additive manufacturing (AFPR) gathers every year the international community of additive manufacturing.

Didier BOISSELIER, expert in additive manufacturing at IREPA LASER, presents the CLAD® process with the selection of the manufacturing strategies de construction. This conference is scheduled on June 22nd at 2.20 pm.

Information and registration ICI

Metal 3D printing : the true industrial solution

Discover the new offer from IREPA LASER

An innovative and economic approach to design and manufacture your parts.IREPA LASER, expert in metal 3D printing, offers its comprehensible range of services :

- Technical and economic analysis

- Selection and optimization of the materials used

- Co-design, re-design

- Manufacturing, repair

- Control and characterization

Our manufacturing solutions : CLAD®, SLM.Download the brochure.

Why choose IREPA LASER ?

Pragmatic approach

Technological leader

Customized services

Innovative solutions

Commitment to impartiality